Simmulation of The-MAP with UEI DAQ (The-MAP : PFK's self-developmented TC-wafer temperature monitoring system) DAQ by UEI(United Electronic Industry) UEI DAQ has 3 slot, Each slot can connected with 12channel module, UEI DAQ can handle 36 channels totally. Main interface of The-MAP

TC Wafer

TC wafer can be made up for 48 TC points

Minimum distance from wafer's edge to TC Point is 2mm

Wafer

2", 4", 5", 6" 8", 12"

Type

K type(Accuracy:0.4% of reading)

R type(0.25% of reading)

S type(0.25% of reading)

TC wire Diameter

0.127mm

0.07mm

(For RTP process 0.07mm is recommendable)

Connector

Di sub Connector

Miniconnector etc..

Max temperature : 1,100℃

Insulation material

: silica sleeve(max temp:850℃),

micro quartz tube(max temp: 1,100℃),

Teflon (max temp: 250℃),

ceramic sleeve, etc..

2 weeks

Vacuum Feed through

Kapton tape will insulate and

protect TC wire and Vacuum rate

10 to-7 torrcan be available.

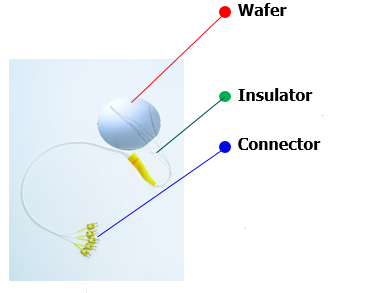

< Structure of TC Wafer >

● Wafer

- SI WAFER, SIO2 filmed Wafer, Cu filmed Wafer, TiTiN filmed Wafer

-GaAs wafer Sapphire wafer, Quartz wafer Glass wafer, etc

● Insulator

-Ceramic fiber (250~ 850C), Quartz(850~1200C)

-Teflon / Polymide(0~250C), Fiber glass(0~450)

● Connector

-Mini connector (Exellent accurancy), Pin connector

- D sub connector, banna plug, bare

● Hole

- The best hole processing idea to minimize heat loss

-User can measure the most accurate

temperature of wafer surface

pfk semiconductor ,instruments

Comments

Post a Comment